Powertrain

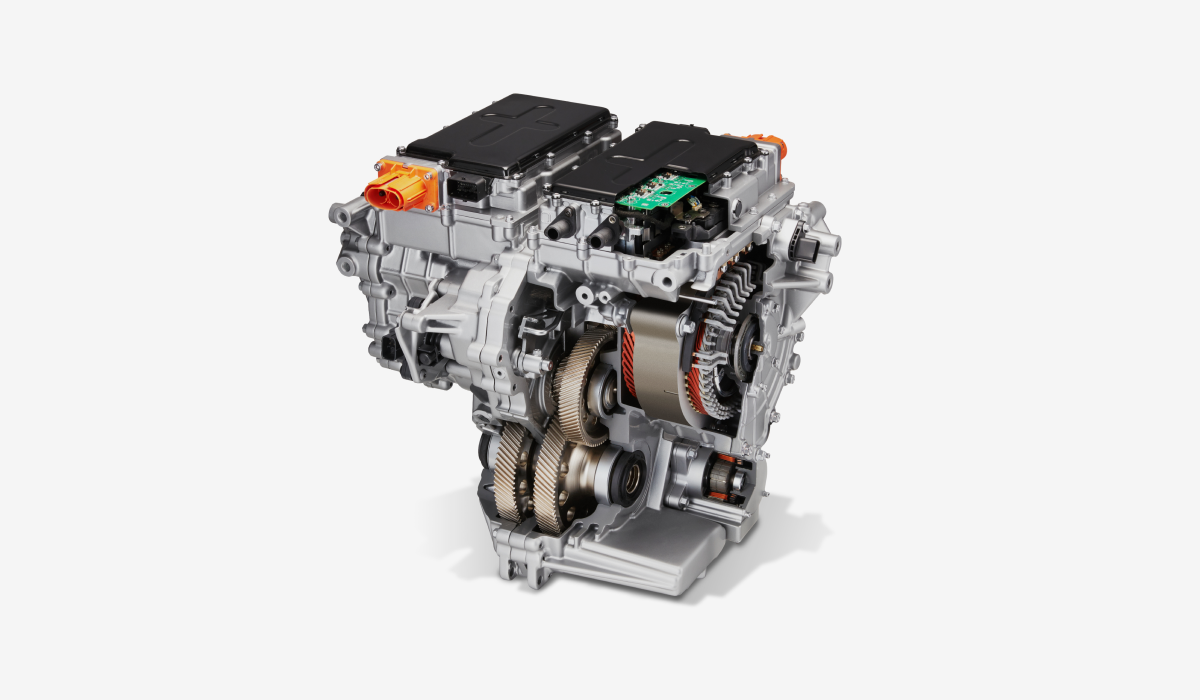

Electric Drive System

HYUNDAI TRANSYS' electric drive system provides the best EV driving experience based on optimized vehicle performance, efficient energy transfer, and excellent control performance.

-

01

Excellent Integration

- 3-in-1 structure (integration of motor, inverter and reducer)

- Design for shortened overall length

-

02

High-performance, High-efficiency Systems

- 800V SiC power modules

- Improved motor cooling performance (direct oil cooling)

-

03

Improved NVH Performance

- Enhanced NVH robustness with an integrated housing structure and a separated input shaft structure

-

04

Improved Fuel Efficiency

- World's first electric vehicle AWD DAS *DAS : Disconnect Actuator System

- Improved mileage of electric vehicles with an 8-10% increase in fuel efficiency

-

01

Excellent Integration

- 5-in-1 structure (integration of 2 motors, 2 inverters and 1 reducer)

-

02

High-performance, High-efficiency Systems

- 800V SiC power modules

- Improved motor cooling performance (oil direct cooling structure)

-

03

Improved NVH performance

- Enhanced NVH robustness with an integrated housing structure and a separated input shaft structure

-

04

Torque Vectoring Implementation

Component

- GDUGear Drive Unit

- The GDU (electric vehicles reducer) controls the motor's rotational speed according to the vehicle's driving strategy, converting it into optimal torque. HYUNDAI TRANSYS offers a wide lineup of reducers suitable for small, large, and high-performance vehicles. Through gear profile optimization, it enhances power transmission efficiency and reduces noise.

- I-DASIntegrated Disconnect Actuator System

- HYUNDAI TRANSYS' world-first disconnect system for electric vehicles (DAS) is a device that can connect or disconnect the motor and drive shaft depending on the driving situation, and can freely switch between 2WD and 4WD. DAS reduces unnecessary power loss and increases power efficiency, contributing to improved mileage of electric vehicles.

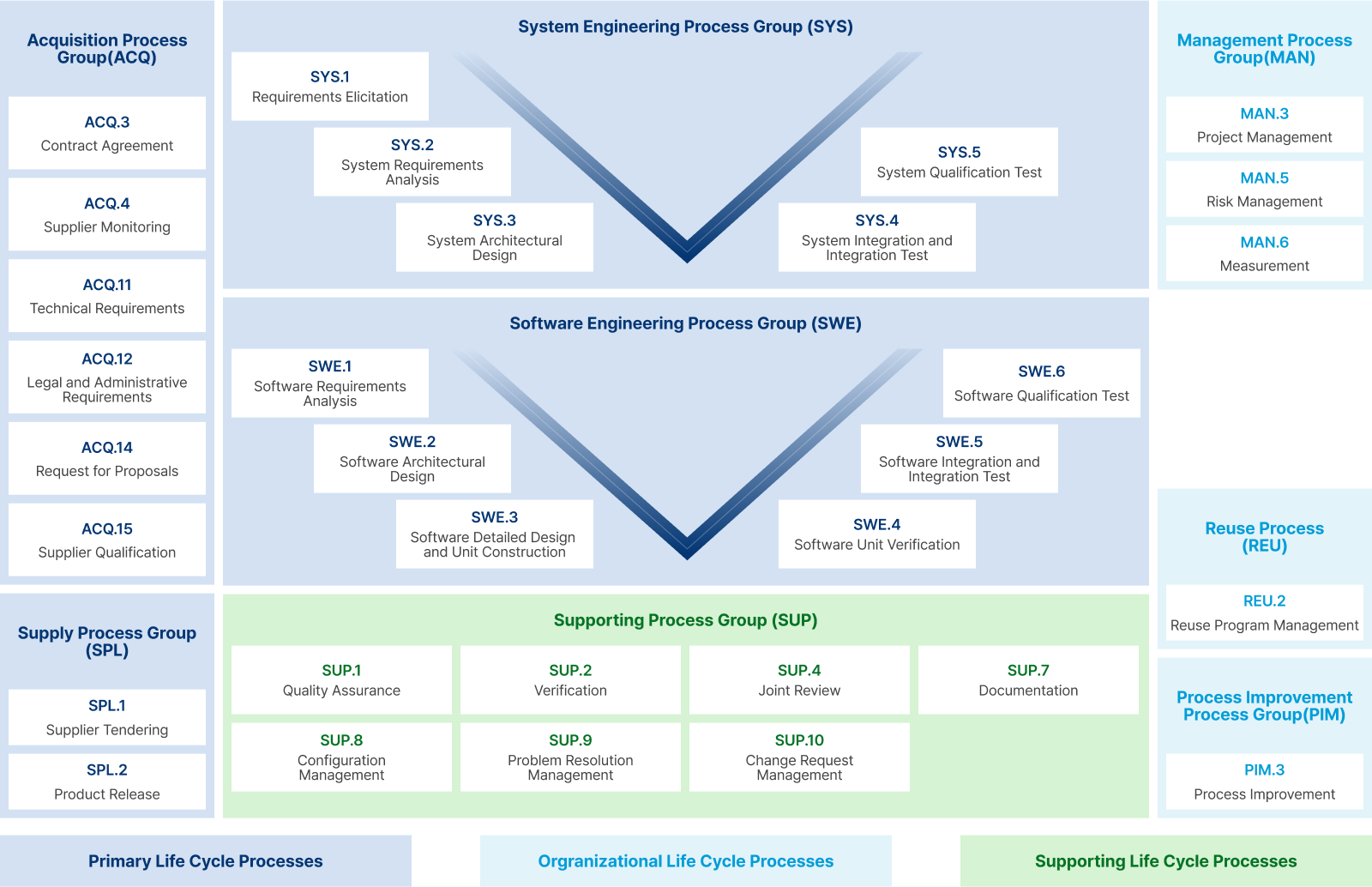

Software

HYUNDAI TRANSYS uses the AUTOSAR platform to configure the inverter software. In order to develop inverters with excellent performance and efficiency, the company is developing inverter software in consideration of various environmental factors. In addition, it has excellent support/response capabilities such as high-speed CAN/CAN-FD support, diagnostic function, cyber response, and calibration through XCP.

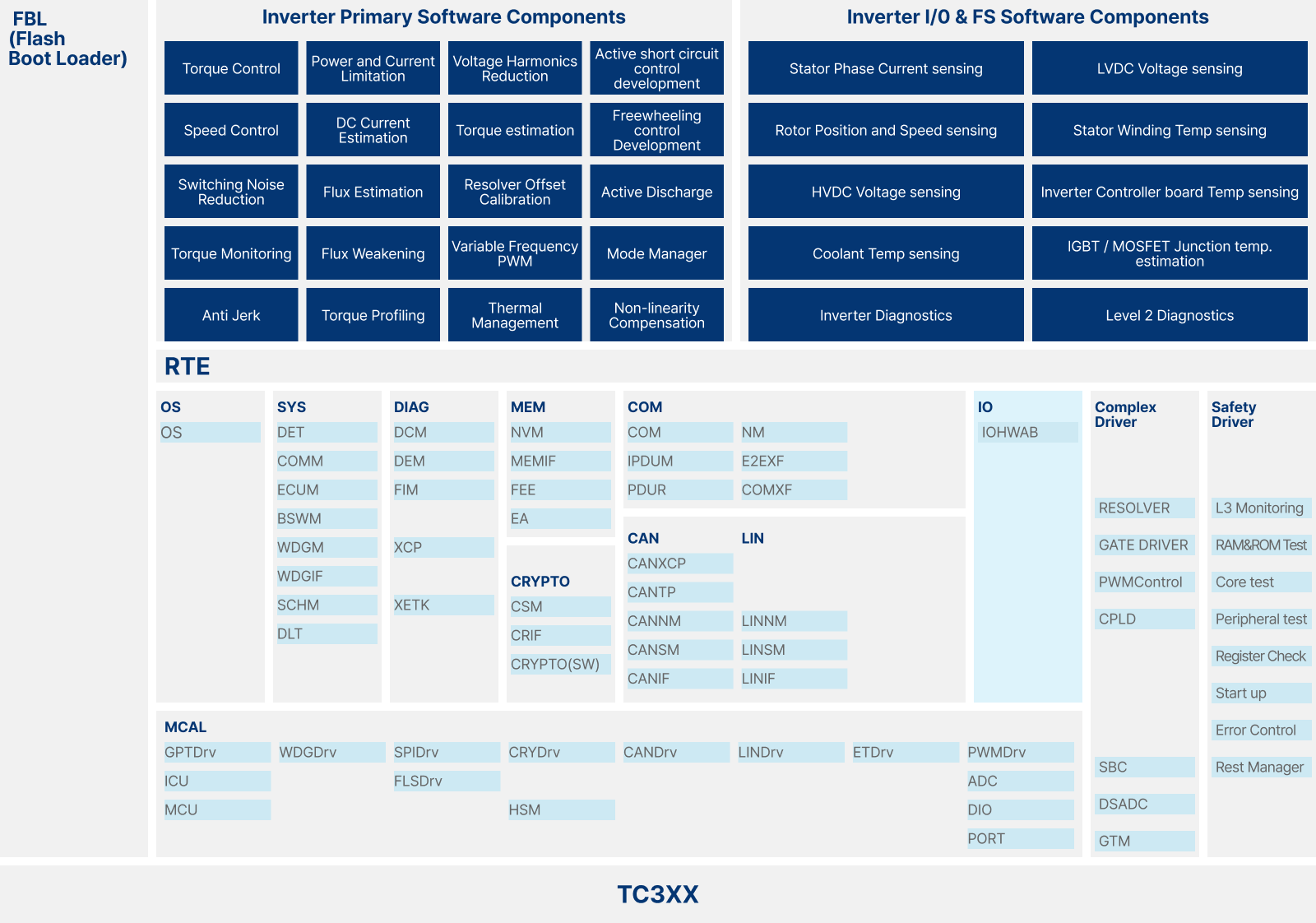

HYUNDAI TRANSYS applies the V-process and ASPICE process for software development. Based on global standards, the company is equipped with the control SW development capabilities to meet customer requirements.