Seating

Sustainable Seat Solution

HYUNDAI TRANSYS makes sustainable seat products with material development and construction methods that consider both nature and humans.

Eco-Seat Roadmap

HYUNDAI TRANSYS develops seats by considering the environmental impact throughout the entire product lifecycle, from product development to post-use disposal. The company adheres to the ELV(End of Life Vehicles) regulations to minimize automotive waste and promote recycling. To develop seats that are environmentally and human-friendly, HYUNDAI TRANSYS has established an Eco-Seat Roadmap and is promoting the development of various new technologies in each area.

- ECO FriendlyNature-friendly technology

-

- Application of natural materials

- Circulation of resource

- Reduction of carbon emissions (lightweight)

- ComfortHuman-friendly technology

-

- Reduction and replacement of hazardous substances

- Satisfaction of 5 SENSEs

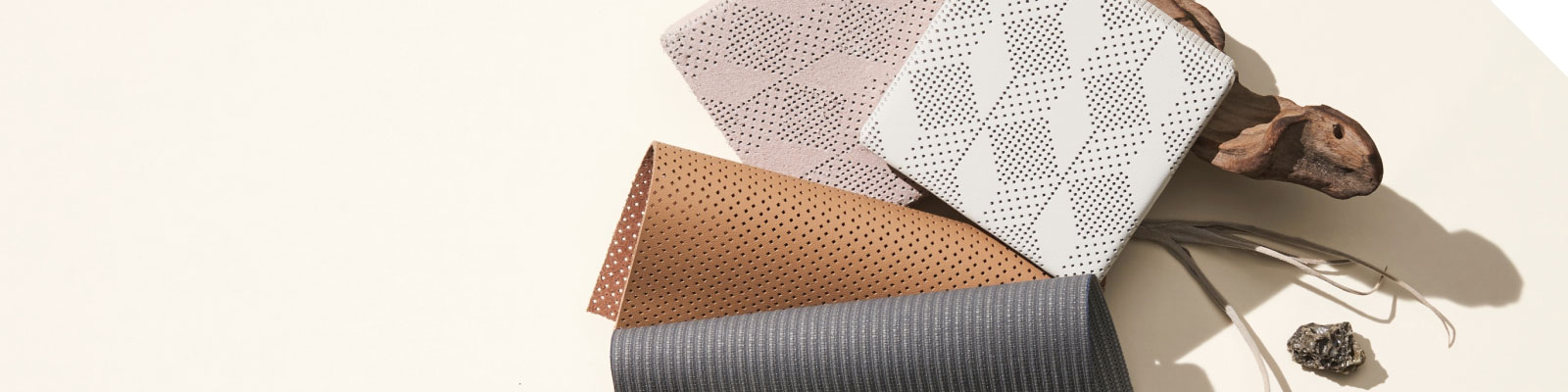

Sustainable Materials

HYUNDAI TRANSYS is developing various seat materials and manufacturing methods, including natural-derived and recycled materials, to increase the proportion of sustainable materials used in seats to over 30% by 2030.

- Bio-foam

-

- Application of naturally derived material (castor seed)

- Bio content 6~12%

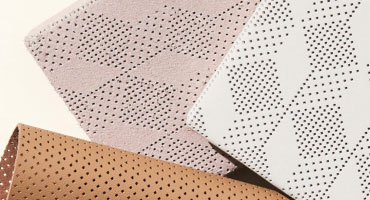

- Bio Synthetic Leather

-

- Application of natural origin material (corn)

- Anti-wrinkle effect

- Bio content 20%

- Silicone Leather

-

- Silicone Leather

- Excellent abrasion resistance and stain resistance

- Carbon dioxide reduction : 18.4kg/unit

- Recycled Leather

-

- Recycling of leather waste (scrap, dregs)

- Minimizing cut loss rate

- Global Recycling Certification (GRS)

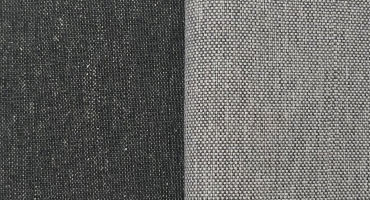

- Fabric made with natural fibers

-

- Application of natural extracted fibers (cotton, hemp)

- Biodegradable properties

- Content: 25% cotton, 10% hemp

- Synthetic leather that substitutes harmful flame retardants

-

- Indo/inorganic flame retardant (substitute for brominated/antimony flame retardant)

- Silicone Antifouling Fabric

-

- Improving stain resistance with silicone-based antifouling agent (substitute for fluorine-based antifouling)

- Securing fabric stability by optimizing the construction method

Sustainable Manufacturing Methods

- PUR Bonding Method

-

- The world's first seat leather upholstering method

- Solvent-free adhesive (no organic solvents/flame retardants harmful to the human body)

- Improvement of wrinkles/lifting, improvement of ventilation performance

- Carbon dioxide reduction 1.25kg/unit

- Reduction of waste generation 0.5kg/unit

- Aqueous Bonding Method

-

- Liquid water-based adhesives (free of volatile solvents)

- Reduction of toxic gas emissions

- Improvement of odor and VOCs

- Cost reduction through process reduction

- Multi-design Punching Method

-

- Improved ventilation by improving ventilation holes (size/accuracy/speed)

- Improvement of appearance quality and various design patterns possible

- Cost reduction through increased productivity